See prior post at: (New Casting Project Enters Planning Phase)

I started by slicing the stone into bread sized slices using a hand saw and a wooden miter box.

Based on the design I came up with each angle cut would need to be 30 degrees. To best insure that I was able to obtain a consistent 30 degrees I created a template. I cute a wood plank at 30 degrees and then used that as my template. As long as the blade of my saw rested on the wood template the cut I made would follow the 30 degree angle.

The following image shows the layout of the cuts I envisioned. After laying out the pieces I found that I would only be able to get three sections out of each slice of stone.

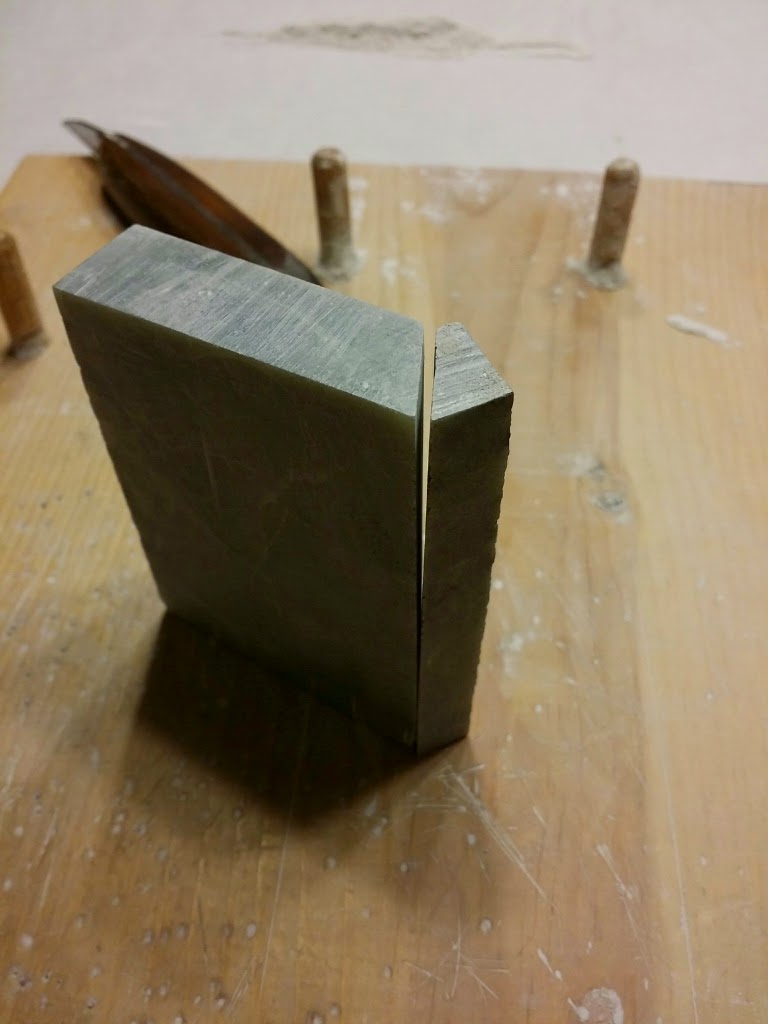

After making the first cut I had to test the shape to see if they would align and work out the way I had envisioned in my head. So far so good I think.

You can see that the second cut was a bit rough. I found that holding the saw at the angle while trying to focus on the angle my hand kept cramping. I could only make the cut about 1/2 way before having to stop and rest. I rather afraid that the cut would bind the saw and then crack the stone. The soap stone is very brittle and making the 30 degree cut was a very slow process.

First full and usable piece cut.

A full set of cut pieces. I may replace one or two of these, but these were the first six successfully cut pieces which I hope will fit together to make the shape you see at the right.

Before spending too much time on the clean up of each piece I cut then all to a consistent length. The final size of the piece is still in question so at this point I simply eyeballed the length. Once I cut one of the six pieces I cut the rest to a length to match.

I tried to maximize the amount of stone I could use and so sliced only thin wafers off the ends to true up the base.

Cut to length it was ready for some clean up. I started with a medium grit sandpaper and progressed to a "fine" grit. I placed the sandpaper on a piece of glass to ensure a flat surface. I then slide each stone over the sandpaper until I was satisfied with a very smooth and even surface.

As this was all hand work there were some minor changes in the angle of the cuts. All six pieces did not align perfectly when placed together. You cannot see the details in this image but there are some cuts which are 1 or 2 degrees off. I plan on creating register pins on each section grouping the mold into two groups of three. Once those two groups are joined together I can then sand the surface flat and true again to correct any imperfections in the cut angle.

Once I got the pieces basically fit together I softened the edges of each stone. After the sanding each stone had very sharp and crisp corners. Those types of edges are more likely to grab, chip and crack the stone when working with them. I took a small metal file and rounded over the edge of all the edges which were not going to be in contact with the finished casting.

Time for another test fitting. I moved the stones around until I could find the best overall fit for each group of three stones. I then marked the stones 1,2 & 3 so that from this point forward they would all have the same relative position.

Repaired!

Quitting time. This is the set of six stones place into their metal box lined with thick wool for safe keeping. I haven't even gotten into any carving yet and I have quite a few hours in this project.

Based on the design I came up with each angle cut would need to be 30 degrees. To best insure that I was able to obtain a consistent 30 degrees I created a template. I cute a wood plank at 30 degrees and then used that as my template. As long as the blade of my saw rested on the wood template the cut I made would follow the 30 degree angle.

The following image shows the layout of the cuts I envisioned. After laying out the pieces I found that I would only be able to get three sections out of each slice of stone.

After making the first cut I used the removed piece to hold the wood template level.

After making the first cut I had to test the shape to see if they would align and work out the way I had envisioned in my head. So far so good I think.

You can see that the second cut was a bit rough. I found that holding the saw at the angle while trying to focus on the angle my hand kept cramping. I could only make the cut about 1/2 way before having to stop and rest. I rather afraid that the cut would bind the saw and then crack the stone. The soap stone is very brittle and making the 30 degree cut was a very slow process.

First full and usable piece cut.

A full set of cut pieces. I may replace one or two of these, but these were the first six successfully cut pieces which I hope will fit together to make the shape you see at the right.

Before spending too much time on the clean up of each piece I cut then all to a consistent length. The final size of the piece is still in question so at this point I simply eyeballed the length. Once I cut one of the six pieces I cut the rest to a length to match.

I tried to maximize the amount of stone I could use and so sliced only thin wafers off the ends to true up the base.

As this was all hand work there were some minor changes in the angle of the cuts. All six pieces did not align perfectly when placed together. You cannot see the details in this image but there are some cuts which are 1 or 2 degrees off. I plan on creating register pins on each section grouping the mold into two groups of three. Once those two groups are joined together I can then sand the surface flat and true again to correct any imperfections in the cut angle.

Once I got the pieces basically fit together I softened the edges of each stone. After the sanding each stone had very sharp and crisp corners. Those types of edges are more likely to grab, chip and crack the stone when working with them. I took a small metal file and rounded over the edge of all the edges which were not going to be in contact with the finished casting.

Time for another test fitting. I moved the stones around until I could find the best overall fit for each group of three stones. I then marked the stones 1,2 & 3 so that from this point forward they would all have the same relative position.

Oops! I set the stone down to abruptly and chipped a corner off. I have heard and once witnessed using "super glue" to repair such a crack. I decided to glue it together and see what would happen. This is one of the two stones I may replace later. Depending on how well the test fitting goes I may try to make a replacement.

Repaired!

Quitting time. This is the set of six stones place into their metal box lined with thick wool for safe keeping. I haven't even gotten into any carving yet and I have quite a few hours in this project.

So far it seems to be coming along basically as I had planned. Next step will be to cut some register pins to group three stones together. Once I have two joined sections I can then treat them as a "two-part" mold and true of the surfaces for those halves.